Non-standard aluminum profiles - designed for the customer

Custom profiles

In our offer, you will find many aluminum profiles with standard cross-sections such as tubes, angles, and flat bars. From these most popular shapes, you can create many complex things. However, sometimes you need to use a custom shape, which you can choose from our catalog of special profiles. If you don’t find the right profile in the catalog, we offer the creation of a dedicated profile for the client.

Aluminum is an excellent material for producing profiles with various cross-sections defined by customers. Thanks to its basic properties, it provides lightweight and strength, and it is also a metal that is well-suited for processing. All these characteristics make it the best material for producing special profiles, used in many industries.

The path of the design process

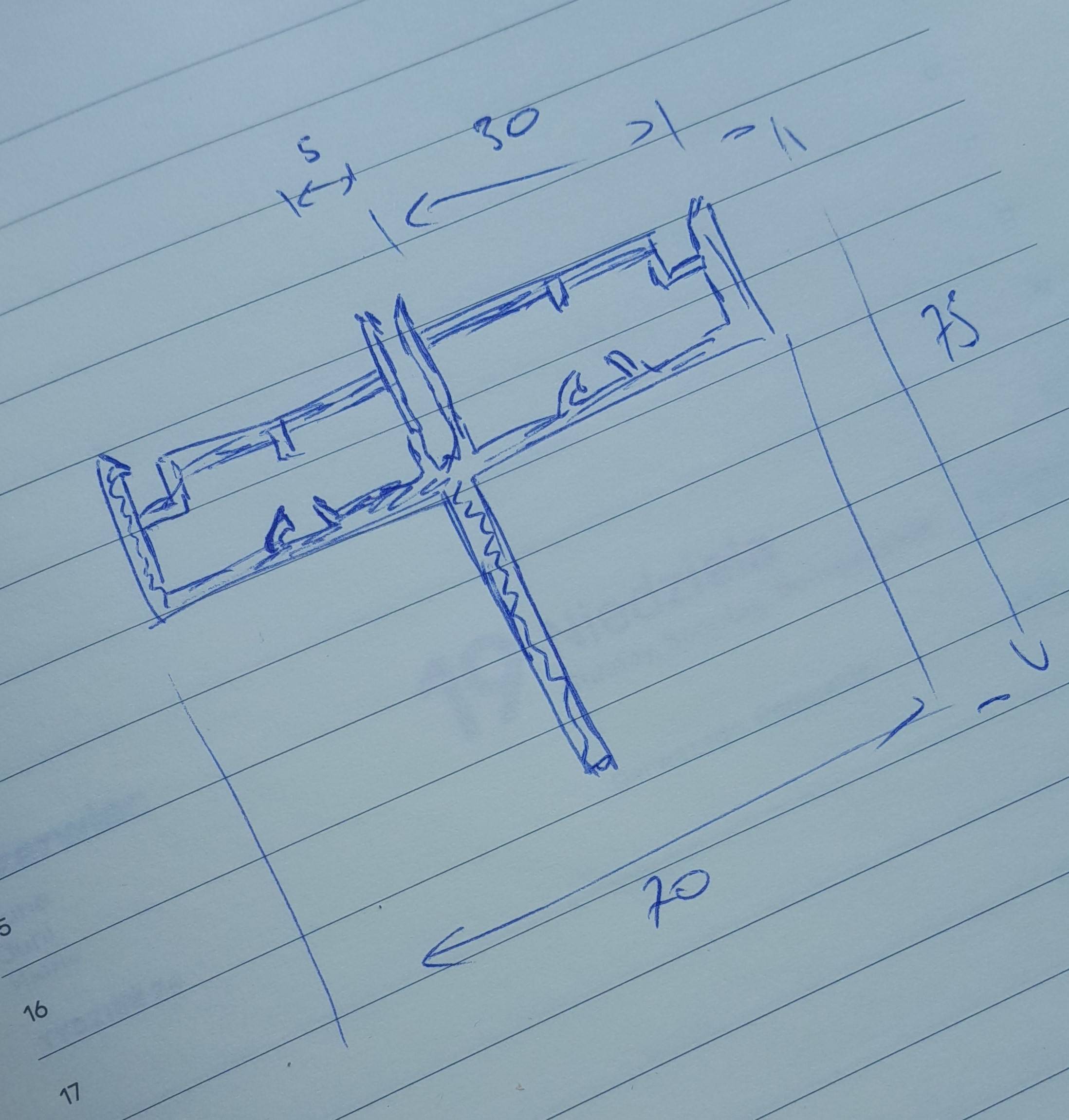

Step 1 – sketch

We start the design process by getting acquainted with the client’s needs.

Sometimes it is expressed in a handwritten drawing, sometimes it is a fragment of the profile on the basis of which the client would like to design his own solution.

Significantly speeds up the profile implementation process when the client has his own technical documentation.

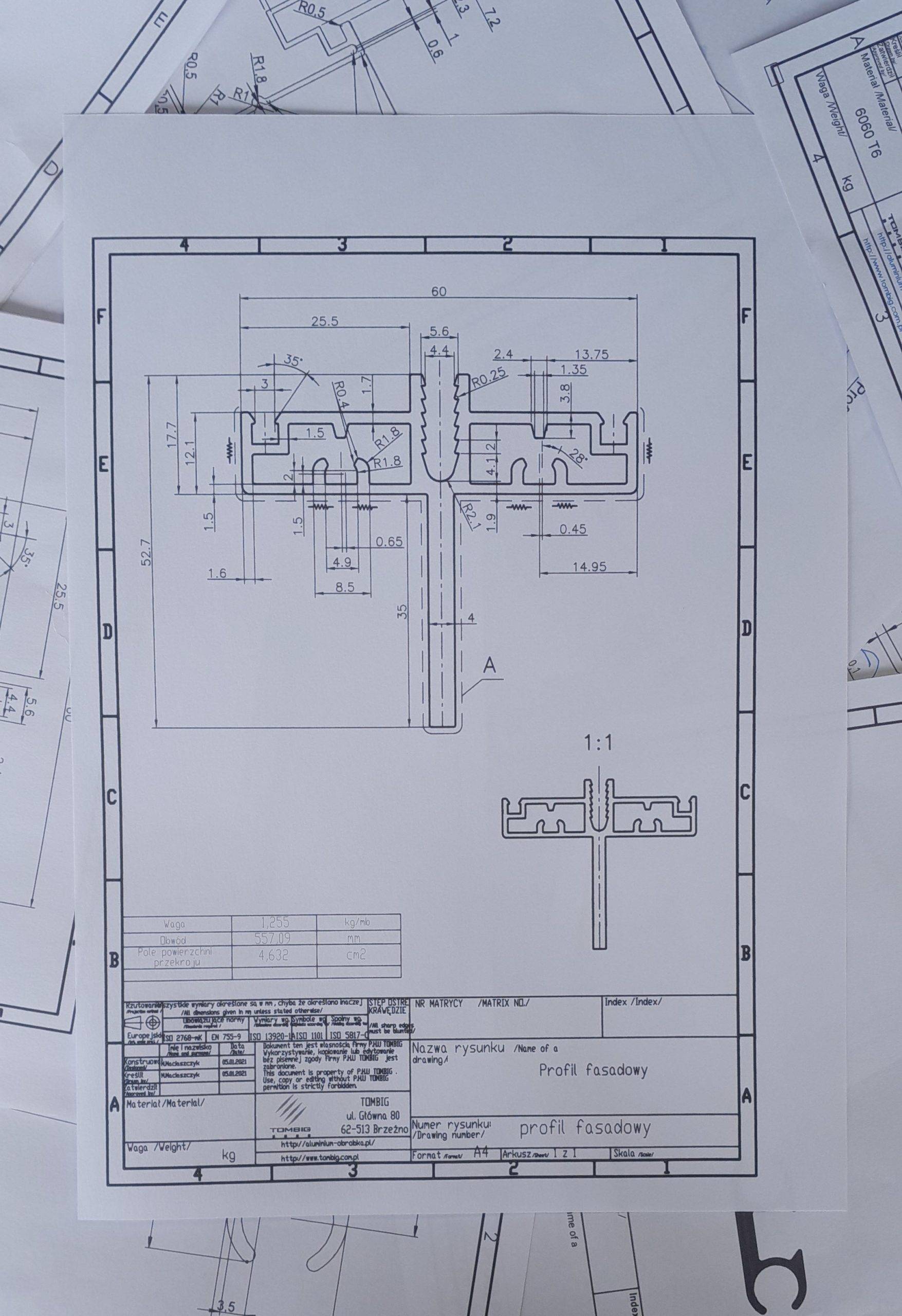

Step 2 – technical drawing

Initial assumptions are sent to the design office, where the assumptions are analyzed, expectations are clarified and information is provided about the possibilities of the material for the implementation of the project.

The next step is to prepare technical documentation, drawings, project weight calculations.

Step 3 – 3D model

When the documentation is ready, communication with the client takes place, if the project is approved, we move on to 3D modeling. We print the profile design at a length of 5-10 cm, so that it can be tested on the model whether the project meets the customer’s assumptions, such as whether the screw holes in the project are of the right size, whether the profile walls meet the strength needs and the like. This is the perfect time to correct the assumptions and complete the project.

Step 4 – generating tools and extruding

With ready and complete paper documentation and technical standards that start the stage of generating matrices, from which it follows that profiles are created. addition to the function from the complexity of the matrix from a few to several days.

Step 5 – produkcion and transport

With the prepared matrix, the project is placed in the production queue, ready profiles are packed in box-pallets and stored in our Distribution Center, then we set the date

and we deliver the order to the customer’s address.

The minimum production quantity is 500 kg, and the precise quantities of profiles are calculated based on the technical drawing and weight calculator. The range of standard profile lengths is 3-7 meters, but values outside this range are also possible to produce, which affects the price.

The price is determined based on the entire order, weight, currency exchange rates ($, EUR), and the price of aluminum per ton on the World Exchange.

Individual stages involve incurring specific costs such as the cost of the project, 3D model, and die. The costs incurred at each step are deducted from the final value of the order. Detailed conditions and delivery time are always determined with the Customer Advisor.

The produced profile design becomes the property of the recipient and will not be available to other customers.

The price is also important, as we know how crucial it is in every purchasing process. Due to the significant market volatility, the price is also highly variable and independent of Tombig’s pricing policy. However, despite such a dynamic raw material market, we deliver the final product to the customer with a price guarantee on the day of the order.

Many of our customers, in addition to custom profiles, also purchase standard profiles such as tubes, angles, flat bars, and many others. You can find their offer here… and special profiles. We also sell sheets: smooth, embossed, and stucco in various sheet sizes and coils. You can find more information about sheets here… Tombig provides precision machining services in CNC centers. You can find more information about the services here..

Feel free to contact the Customer Advisor from Monday to Friday

in person at the Tombig headquarters in Brzeźno, ul. Main 80,

by phone, e-mail or via the form.

Tomasz Michalak

Project Specialist

I assist clients in the decision-making process regarding the choice of alloy, wall thickness, and cost optimization. On each profile, I will help plan the execution of mechanical processing and the application of coatings.

I supervise the production process and delivery of ready-made custom and special profiles to the client

The final product is usually the color of raw aluminum – silver-white.

We offer an anodizing service that will give a pastel shade of gray and additionally protect the metal surface.

We are also able to deliver ordered profiles varnished in the color specified by the customer.

– automotive,

– arms industry,

– aircraft,

– furniture industry,

– advertising and promotion,

– exhibition industry,

– electronic industry,

– construction,

production of measuring tools and devices,

– railways,

– Food industry

– production of agricultural machinery.