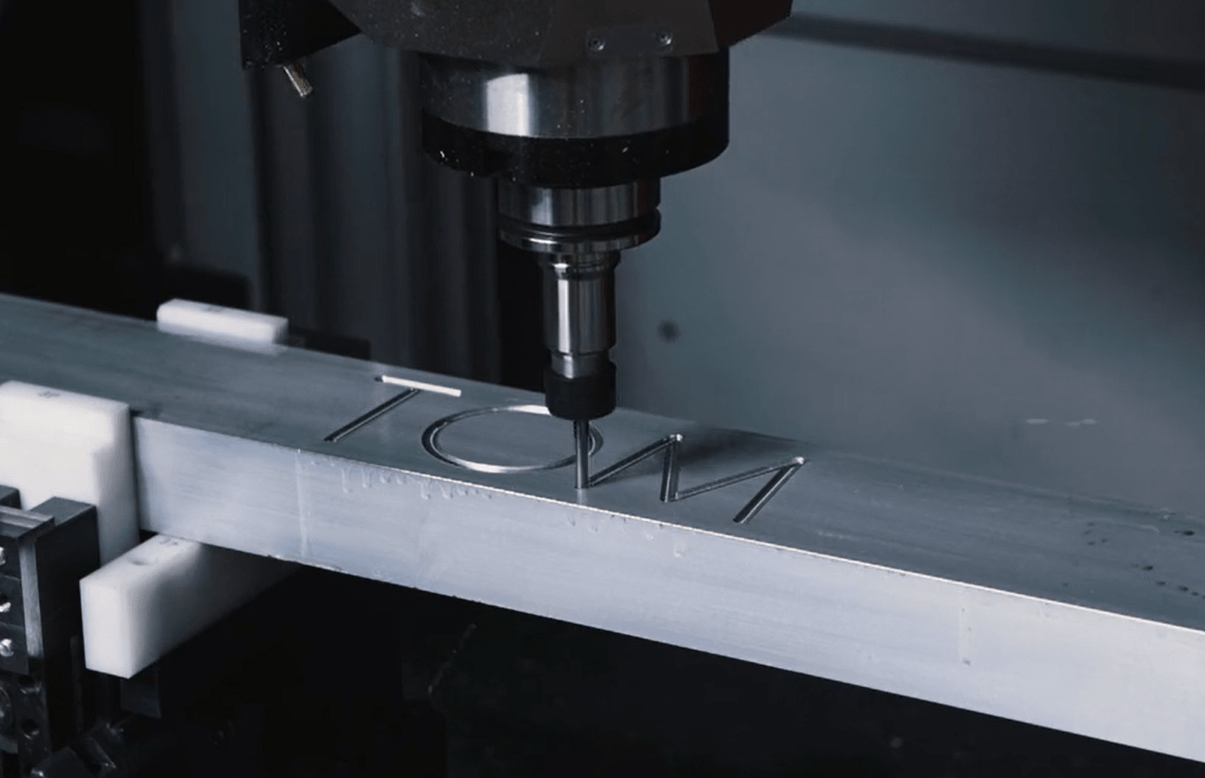

CNC machining

CNC machining centers

Computer Numerical Control (CNC) machines allow for precise and efficient execution of specific shapes on a given material.

We offer services on both standard and special profiles purchased from Tombig.

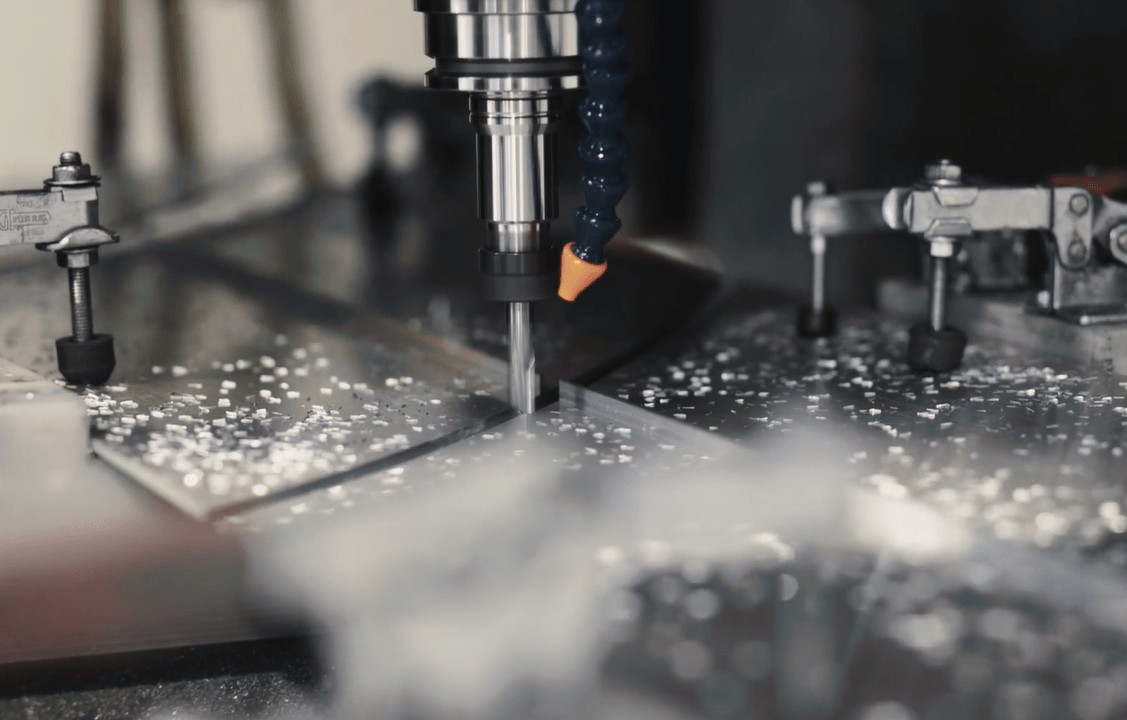

The service execution consists of three stages:

- Computer-Aided Design (CAD)

- Machine control programming (CAM)

- Machining execution (CNC)

We can handle all stages independently, but based on our experience, the best solution is for the client to provide us with CAD files.

Our services are based on Elumatec devices. The working length of the semi-finished products includes SBZ 151 ed. 90 – 7.3 m (excluding the front surface) and SBZ 140 – 9.7 m (excluding the front surface). Each device is equipped with a tool magazine that can hold 8 to 13 elements (drills, mills, discs)” [1].

I hope this translation accurately conveys the meaning of the original text. If you have any further questions, feel free to ask!

Cutting

Threading

Shape chamfering

Cutting out the shape

Milling

Drilling

Elumatec CNC SBZ 140

- 4-axis profile machining centre

- Designed for economical and efficient machining of aluminium and thin-walled steel profiles

- Standard version with air-cooled router spindle (version with water-cooled router spindle available optionally)

- All operations, such as routing, drilling and tapping, are performed while the profile bar is stationary to protect the profile surfaces

- Machining with all tools at angles continuously adjustable from -90° to +90°

- Automatic clamp positioning with absolute measurement system

- The on-board tool magazine ensures that tool changing times are kept short, thereby optimizing machining cycles

- The magazine can be equipped with eight tools

- Up to two rotating angle heads with two different tools are optionally available for double-bar and end machining (0° – 90° – 180° – 270°) (optional)

- Two separate working zones enable machining in shuttle operation (optional). There is a central laser scanner on the operator’s side to protect the area for maximum safety.

- 4-axis controller

- 18.5″ colour display, USB ports and network connection

- Windows operating system

- eluCam

Machining lengths

SBZ 140 – 7.6 m

- Max. machining length with profile end machining, 7,600 mm

- Max. machining length without profile end machining, 7,720 mm

SBZ 140 – 9.7 m

- Max. machining length with profile end machining, 9,700 mm

- Max. machining length without profile end machining, 9,820 mm

Options

- Shuttle operation for working on two sides

- Automatic length measurement on both sides

- Clamping unit accommodates double profile machining

- Barcode scanner

- Stationary tool magazine (16x)

- On-board tool changers for angle head or saw head

- Angle routing heads

- Saw head

- Tool holders

- Collet chucks

- Collets

- Tools

- eluCad (office software package for optimised production management)

źródło: Elumatec

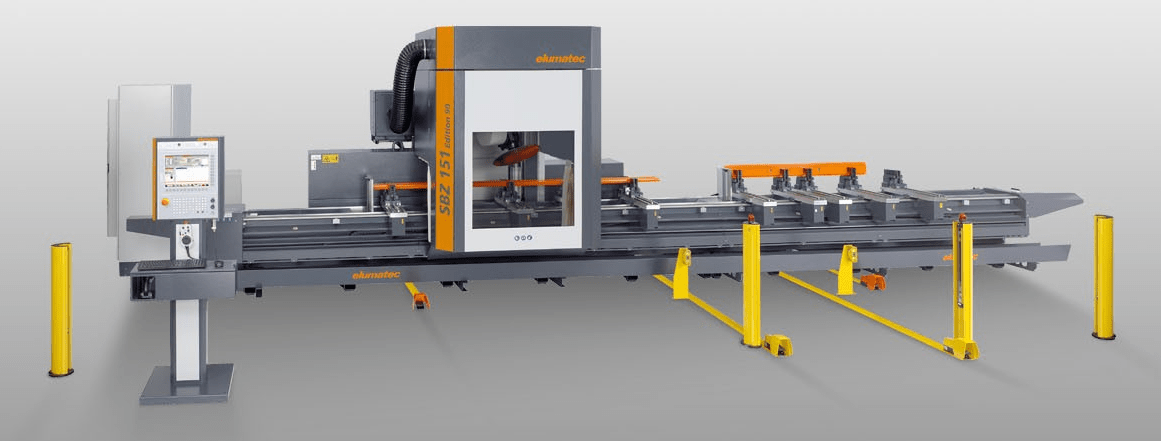

Elumatec CNC SBZ 151 ed. 90

- 5-axis profile machining centre

- Designed for flexible and efficient machining of aluminium and thin-walled steel profiles

- All operations, such as routing, drilling, tapping, thread milling, notching and sawing, are performed while the profile bar is stationary to protect the profile surfaces

- Fast positioning of the machining unit with up to 66 m/min thanks to dynamic servo drives

- 6-sided machining. From below with an angle head (optional)

- The on-board tool magazines ensure that tool changing times are kept short, thereby optimizing machining cycles

- One magazine can be equipped with 13 standard tools and seven special tools (angle routing head and special cutters). An additional magazine for the saw blade,

diameter 400 mm or 500 mm

- Autonomous clamp positioning with absolute measurement system

- Two separate working zones enable machining in shuttle operation. Secure access with safety fences and light barriers

- 5-axis CNC control with independent CNC for 3D machining, notching and cutting

- The absolute rotary encoder system means no axis homing is required

- Network connection and USB port

- Operating terminal with Windows operating system and 15″ flat screen

- Remote online maintenance

- eluCloud ready

Machining lengths

SBZ 151 Edition 90 – 7.3 m

- Max. machining length with profile end machining, 6,980 mm

- Max. machining length without profile end machining, 7,300 mm

Options

- Automatic length measurement on both sides

- Automatic length measurement on both sides with Z travel

- Tool length measurement and fracture detection

- Tapping without compensation chuck

- Clock system

- 3D wireless measurement sensor

- Tools

- Tool holders

- Collet chucks

- Collets

- Angle routing heads for machining from below

- Saw blades

- Chips conveyor belt

- Vapour extractor

- Label printer

- Barcode scanner